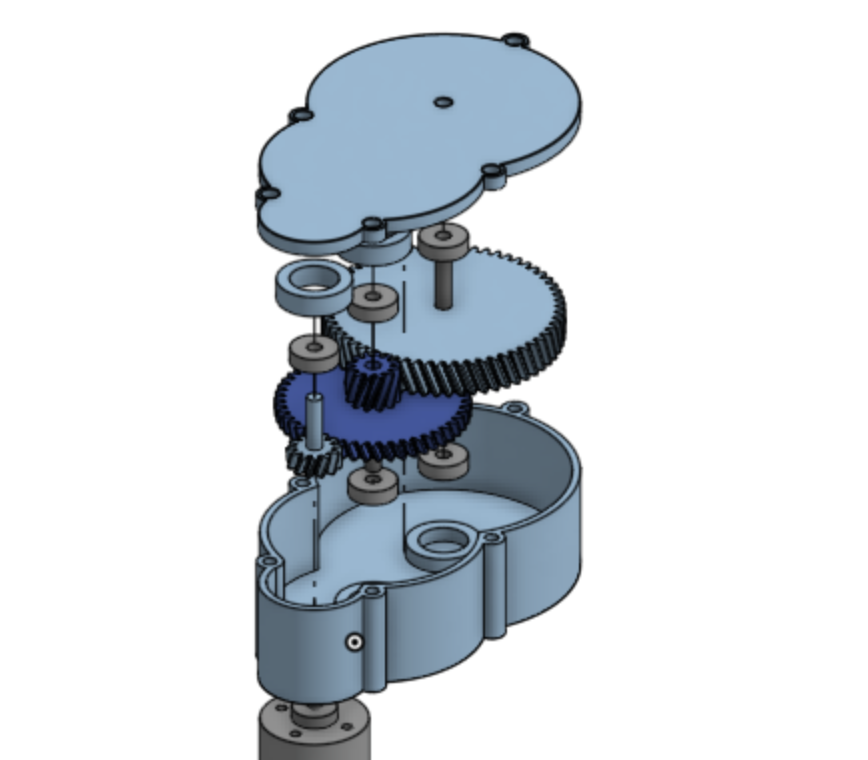

High-Torque 20:1 Helical Gear Reduction Drive

Designed and fabricated a custom two-stage reduction gearbox to convert high-speed DC motor input (10,000+ RPM) into high-torque output for robotic actuation. The project served as a targeted exercise to improve CAD modeling, Design for Manufacturing (DFM), and Geometric Dimensioning and Tolerancing (GD&T) skills.

Parametric CAD

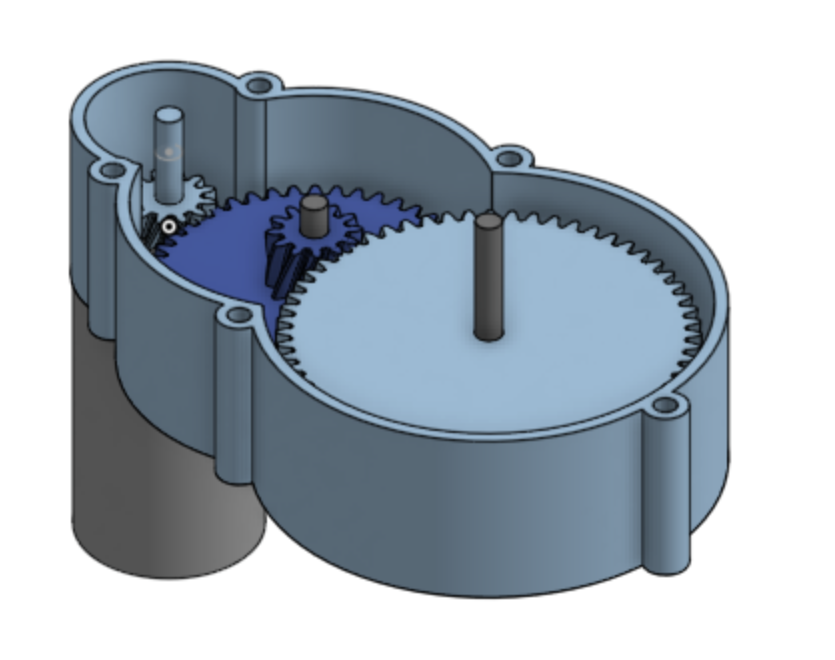

Using Onshape, I modeled a complex assembly where the housing geometry is parametrically linked to a helical gear train. I utilized a specialized gear tool to generate Module 1.5 profiles with a 20° helix angle, prioritizing smooth power transmission and noise reduction.

DFM (Design for Manufacturing)

To manage the axial forces generated by helical gears, I seated bearings on a solid 5mm floor enclosed by reinforced, friction-fitted slots. This ensures the housing remains rigid.

GD&T (Geometric Dimensioning and Tolerancing)

I toleranced the case to account for the physical constraints of FDM printing. Since the printer follows a center-line path and extrudes material roughly 0.2mm over both sides of that line, I implemented a consistent 0.2mm offset across all critical features (motor and bearing mounts, shaft clearances). This successfully compensated for material overflow and shrinkage, ensuring precise fitment across all mating components.

DFA (Design for Assembly)

To ensure a robust and serviceable enclosure, I integrated brass heat-set inserts throughout the housing, secured with M4 bolts. This approach allows for high clamp loads and repeatable, wear-free maintenance cycles, providing a much more durable mechanical connection than threading directly into the 3D-printed plastic.

Results

The project resulted in a fully operational 20:1 reduction drive that effectively manages high-velocity inputs and complex axial forces within a compact, 3D-printed form factor. The final assembly achieved perfect mechanical alignment, producing a quiet, high-torque output suitable for high-load robotic applications.